The Bauer Nanobubbles Processor

The Bauer Processor is a highly engineered device that is integrated into commercial or industrial water systems. The critical output of the processor is the creation of unique Bauer nanobubbles.

Bauer nanobubbles empowers the performance of water to eliminate biofilm in industrial process applications.

The Bauer Processor introduces nanobubbles with unique properties that are far superior to traditional chemical methods. The result is a breakthrough in energy efficiency, filtration and productivity.

Bauer Nanobubbles Mode of Action

- Nanobubbles are hydrophobic: they repel water and are attracted to particle’s surfaces.

- Particles in the water serve as seeds where nanobubbles are formed.

- Proprietary controlled cavitation produces hydrophobic, negatively charged nanobubbles on the seeded surfaces thereby encapsulating the particles. Thus, their zeta potential is lowered, resulting in the particles coagulating. These coagulated particles are naturally agglomerated and exponentially increase in size and therefore are very easy to filter out and due to their neutral charge characteristics are unable to adhere to surfaces.

This Mode of Action is a patented, novel discovery and cannot be replicated

by other gas-infusion nanobubble technologies.

Bauer Processor Mode 1 – Obtain a Net Zero Charge of Minerals

Two Bauer Processors are employed in a series with chemical injection for both raw and well water applications:

- In the first processor, minuscule amounts of gases in the form of dissolved air in the water, usually containing between 6 and 8 ppm of oxygen in the water, are converted into extremely small nanobubbles, which attach themselves onto the surfaces of the agglomerated cations and anions.

- As a result of this, both soluable/insoluble cations and anions in the water are brought to a net zero charge which causes them to separate and agglomerate unto themselves.

Bauer Processor Mode 2 – Super Oxidation of Minerals

- After water exits the first Bauer Processor, a chemical such as Chlorine or Chlorine Dioxide is proportionally injected in very small doses of 2-3 ppm to oxidize the soluble minerals.

- The Chlorine or Chlorine Dioxide gases are converted into very small nanobubbles and are able to control bio fouling of the water system*.

- These chemical nanobubbles are very robust and persist throughout the entire water filtration and water distribution system.

* No other nanobubble generator is able to convert a dissolved gas into a bubble.

Bauer Processor Mode 3 – Filtration

- Filtration is simplified and greatly enhanced due to the absence of gases and bio fouling. No other filtration system has this attribute.

- No chemical cleaning is required as a result of there being no bio fouling. Overall maintenance of the system is reduced by twenty fold on an annual basis.

Bauer Processor Mode 4 – UV Sterilization

In a patent-pending application, the Bauer Mode of Action to convert

the chemistry into a nanobubble allows for the sterilization of the

water by a high-powered UV system greater than 200 millijoules

without the photo catalysis of the chemistry.

The bubble reflects the UV light and protects the chemistry

This is a major advantage for most water treatment systems as

chemistry is not able to destroy many pathogens.

Bauer Processor Mode 5 – Biofilm Removal & Prevention

- Due to the large volume of very small, persistent nanobubbles, each one having a very high Oxidation Reduction Potential, biofilms are destroyed continuously through cell lysis and oxidation.

- The very small nanobubbles (<70nm) also allow deep cleaning and the removal of difficult surface contaminates such as Titanium Dioxide.

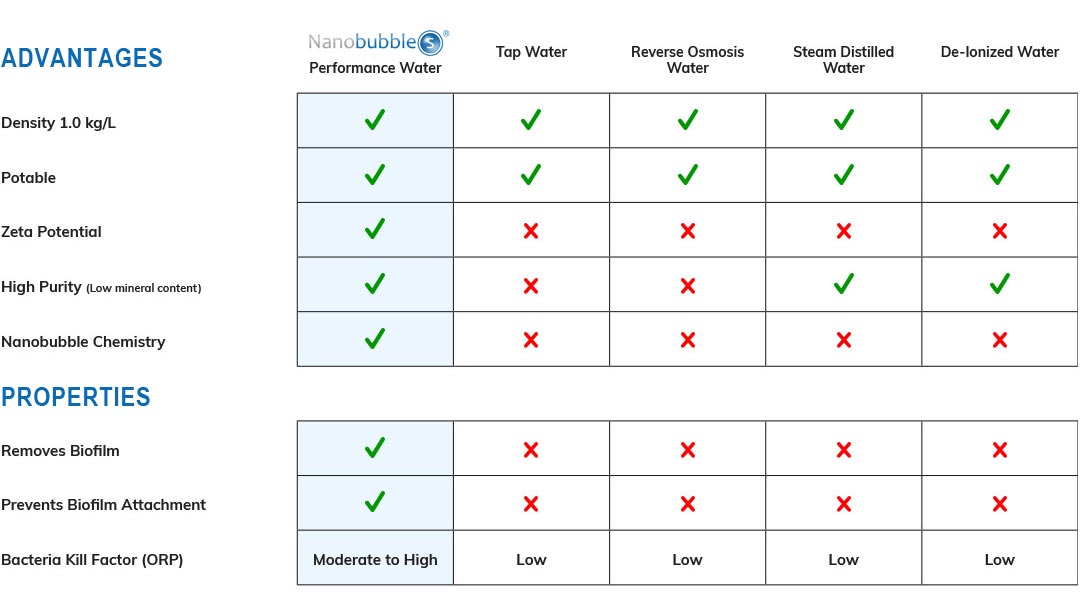

Bauer Processor Effects on Water

The Bauer processor forms approximately 300,000 to 500,000 nanobubbles per droplet. This is extremely difficult to measure, however, the processed water exhibits the properties of water containing nanobubbles in terms of cleaning and biofilm removal observed in literature, implying that the small particles observed in the water are nanobubbles.

Zeta potential is also reduced, which allows particles that are too fine to filter to combine into particles large enough to be caught in standard filtration media. Zeta potential is the force of repulsion between particles, while van der Waals forces attract the particles together. When fine particles will not stick together, zeta potential is the dominant force.

Before processing, the particles are similar to two magnets of the same pole: they are repulsive. Imagine trying to place one on top of the other. Although gravity (van der Waals forces) is pushing them together, the magnetic force (zeta potential) is too strong.

The reduction of zeta potential after processing is similar to removing the magnetic force from the two magnets: gravity will dominate, and allow the magnets to be placed one on top of the other. In water, particles that are positively and negatively charged experience a zeta potential shift toward 0mV. When this occurs, they are able to form larger particles, which are collected and observed in filtration systems.

An additional change in the water is a rise in ORP (oxidation-reduction potential). Although the mechanism for this has not been tested, it is likely the result of micro bubbles forming in the Bauer processor and then imploding, which releases free radicals and raises the ORP; this is consistent with literature.

The ORP rise can assist in the sanitizing properties of the water, as raising the ORP decreases the time it takes for free floating pathogens to be killed in solution. Also, fine metal particles are not soluble in higher ORP solutions.

The creation of nanobubbles without the addition of any new gas to the water is the phenomenon of the Bauer Processor. The processor is comprised of a sophisticated pattern of chambers and shear planes.

As water flows through the Bauer Processor a controlled endothermic reaction occurs to create a high concentration of nanobubbles which naturally alter the equilibrium of the water molecules resulting in enhanced performance properties.

Iron Removal Via Nanobubbles

Iron, combined with silica and other minerals form biofouling (iron bacteria).

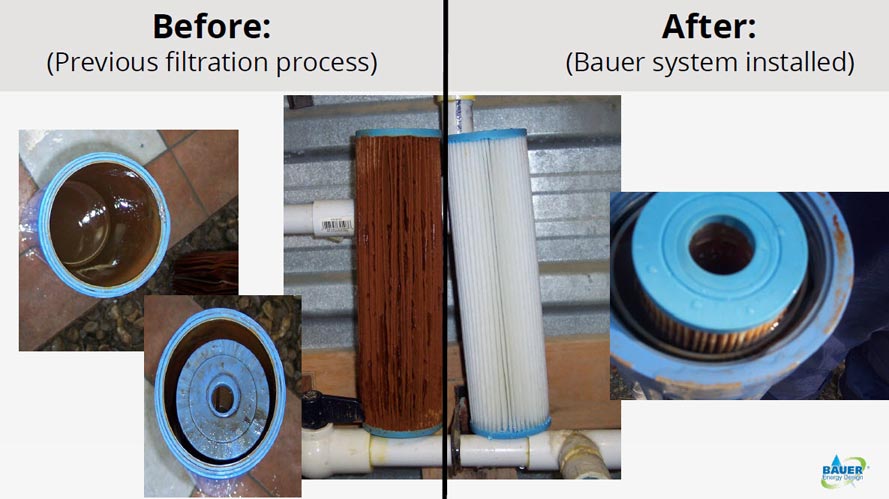

The following image exhibits the before and after photos of the Bauer water systems at KNF Farms in Elmira, ON. The filters are the “downstream filters” located inside each individual barn.

Prior to arriving at the barn, the well water was first processed in KNF’s main water-room facility where the

initial (before) commercial filtration process was run. The “after” photos shows the results on the filters of the Bauer systems, once installed. Both the before and after photos were taken after 2 weeks of use.

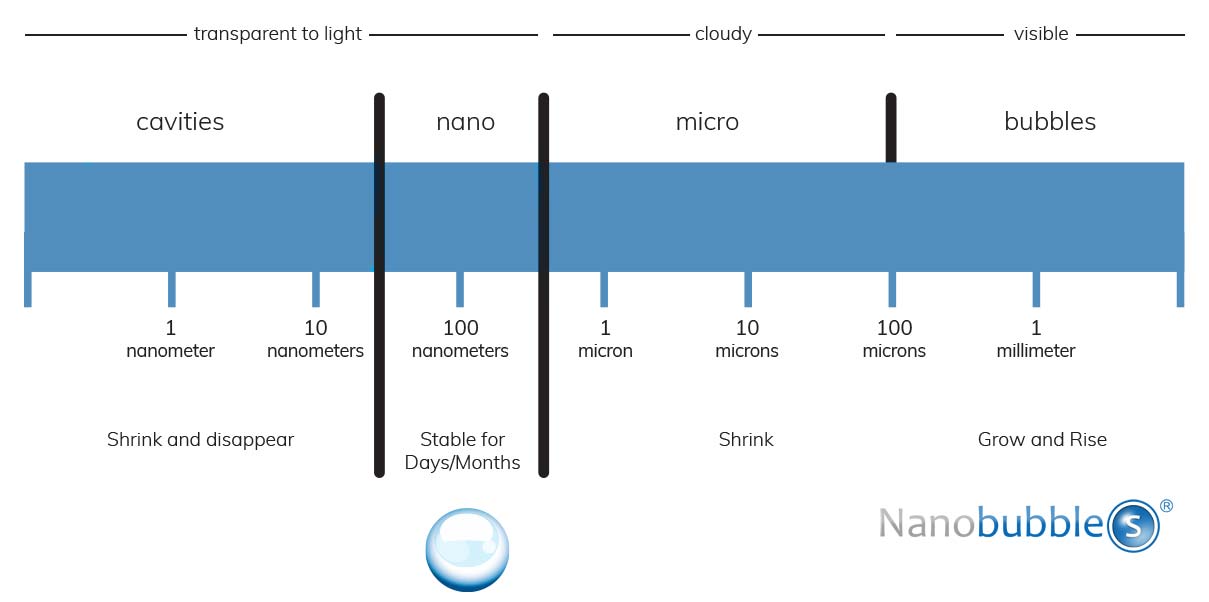

The Nanobubble

Bauer nanobubbles are less than 100 nanometers* in diameter, with over 300,000+ measured in a single drop of Bauer Performance Water.

Nanobubble Size Chart

Net Zero Charge

Use of the Bauer Processor changes the Zeta Potential of suspended colloids in the water, allowing the charge to approach zero.

When this occurs, the particles are able to agglomerate (particles merge, creating clusters), which can be filtered out of the water.

Oxidation Reduction Potential (ORP)

ORP is a measurement associated with the potential for a chemical (in this case water) to oxidise. Oxidation is often used to kill bacteria in solution.

The higher the ORP, the faster the bacteria are killed/oxidized. Bauer Performance Water has a higher ORP than other water types, which allows it to kill bacteria more readily.