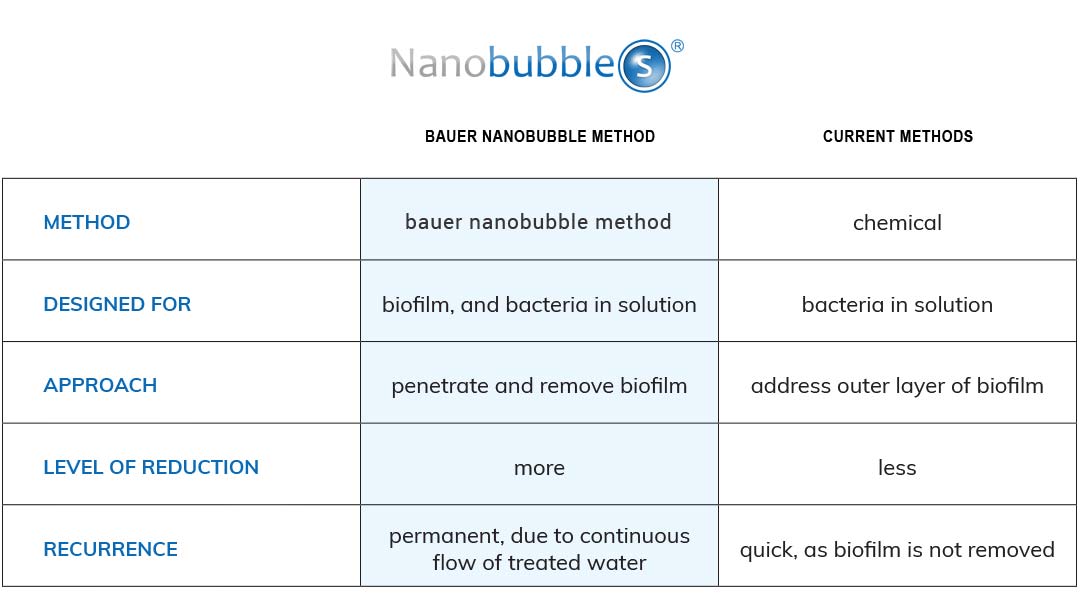

The Bauer Nanobubble Processor is a Superior Biofilm Remediation Method.

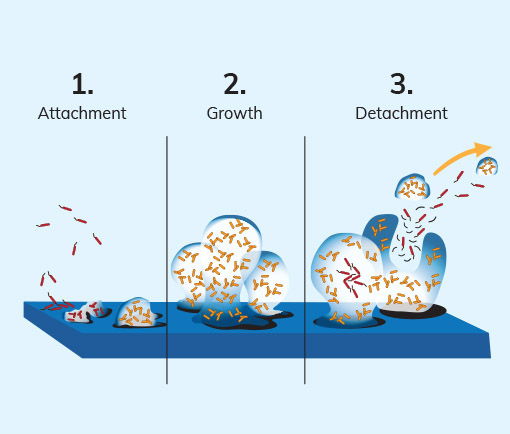

Biofilm is present in any system containing water and a solid surface. It is a matrix of microorganisms that forms quickly once water contacts the solid surface. Biofilm has many negative impacts on systems, including becoming a reservoir for pathogenic bacteria, and greatly reducing heat transfer in systems.

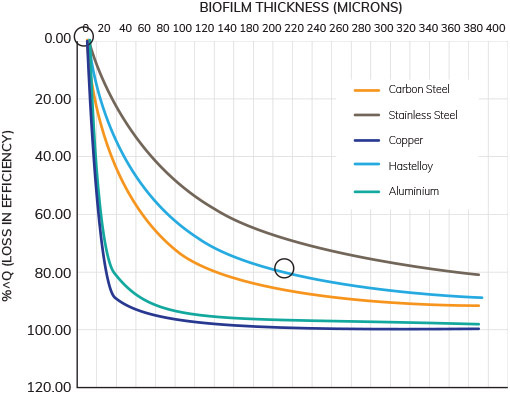

Ten microns of biofilm can reduce heat transfer by 20% or more, depending on the material the system is composed of. Once microorganisms merge with the biofilm, their DNA changes, allowing the biofilm to be resistant to standard cleaning methods, including chemical treatment.

Biofilm is Pervasive in All Standard Water Systems.

Biofilm Removal

Biofilm removal is a known result of contact with water that has an abundance of nanobubbles. As Bauer processor water likely contains 300, 000 to 500, 000 nanobubbles per droplet, it is implied that it is capable of removing biofilm by penetrating through the biofilm, breaking it up. As there are other changes to the water once it has been processed, it is possible that other changes also play a role in biofilm removal.Dr. Xi has completed a study, showing the ability of Bauer Processed water to both remove and prevent the growth of biofilm. In an eight day period, the attachment of biofilm in Bauer Processed water decreased by 80%, and when it was introduced to systems already containing existing biofilm, it was able to remove 99% more biofilm than control tap water in times spans as short as 10 minutes

Bauer processed water has many positive effects on water systems. It is able to remove and prevent regrowth of biofilm. It is implied from current literature that this is an effect of the nanobubbles that are contained in the processed water. It is possible that other properties of the water also impact the biofilm reduction.

The Bauer processor also forces fine impurities to merge into larger particles which can be filtered out of the water; the Bauer process allows impurities remaining from standard city water treatment to be removed.

Biofilm is Naturally Occurring Yet Potentially Harmful.

- Biofilm forms in environments where water meets a surface.

- Microorganisms (bacteria, fungi, viruses) merge and grow into a complex matrix that attaches to surfaces.

- Microorganisms thrive and grow in the biofilm environment, which offers protection from antibiotics and biocides

- Biofilm is very difficult to remove, especially without the introduction of physical and chemical measures, which are often ineffective, or potentially harmful to human health

- Biofilm is difficult to detect, even in well maintained systems.

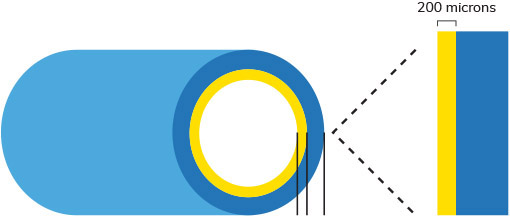

- The thickness of biofilm could be 200 microns, which is virtually imperceptible.

- Yet 200 microns of biofilm has a profound negative impact on heat transfer efficiency.

Heat Transfer Applications

Biofilm begins growing immediately when water comes in contact with surfaces, and continues to grow and evolve to the environment. Currently, biofilm is a commonly accepted hindrance in heat transfer, as until now, there were no known methods of removal that were capable of effectively removing it, and certainly no methods to prevent formation.

The microorganisms that combine to make the complex biofilm matrix are highly adaptable, regenerating the biofilm at greater speeds than they initially formed after chemical cleaning methods are applied, causing the system to require even more frequent cleaning.

Heat Transfer is Dramatically Impacted by Only Microns of Biofilm.

Biofilm has been measured to have a thermal resistance of 1.6 m.K/W (5). To compare, the thermal resistance of copper is approximately 0.0026 m.K/W, while the thermal resistance of wool felt is approximately 2.5 m.K/W. Although wool felt has a higher thermal resistivity than biofilm, it is certainly in the same range.

The amount of extra energy required to heat or cool a building due to heat transfer hindrances is similar to trying to keep cool on a hot summer’s day while wearing a wool sweater.

- The efficiency of heat transfer decreases significantly with small layers of biofilm (200 microns).

- Biofilm lowers the amount of heat that can be transferred by acting as insulation.

- Note that nearly 80% of efficiency is lost in a hastelloy pipe between 0 and 200 microns of biofilm.

- Even a 10 micron layer of biofilm in copper pipe can reduce heat transfer efficiency by 72%.

To Achieve Maximum Heat Transfer Gains, Biofilm Needs to be Virtually Removed.

- The greatest impact of biofilm on heat transfer is within the first 100-200 microns.

- The biggest increases in efficiency from reducing biofilm are in materials that have very high conductivity, eg. Copper and Aluminum, specifically when the biofilm thickness approaches 0 microns.